What our customers say

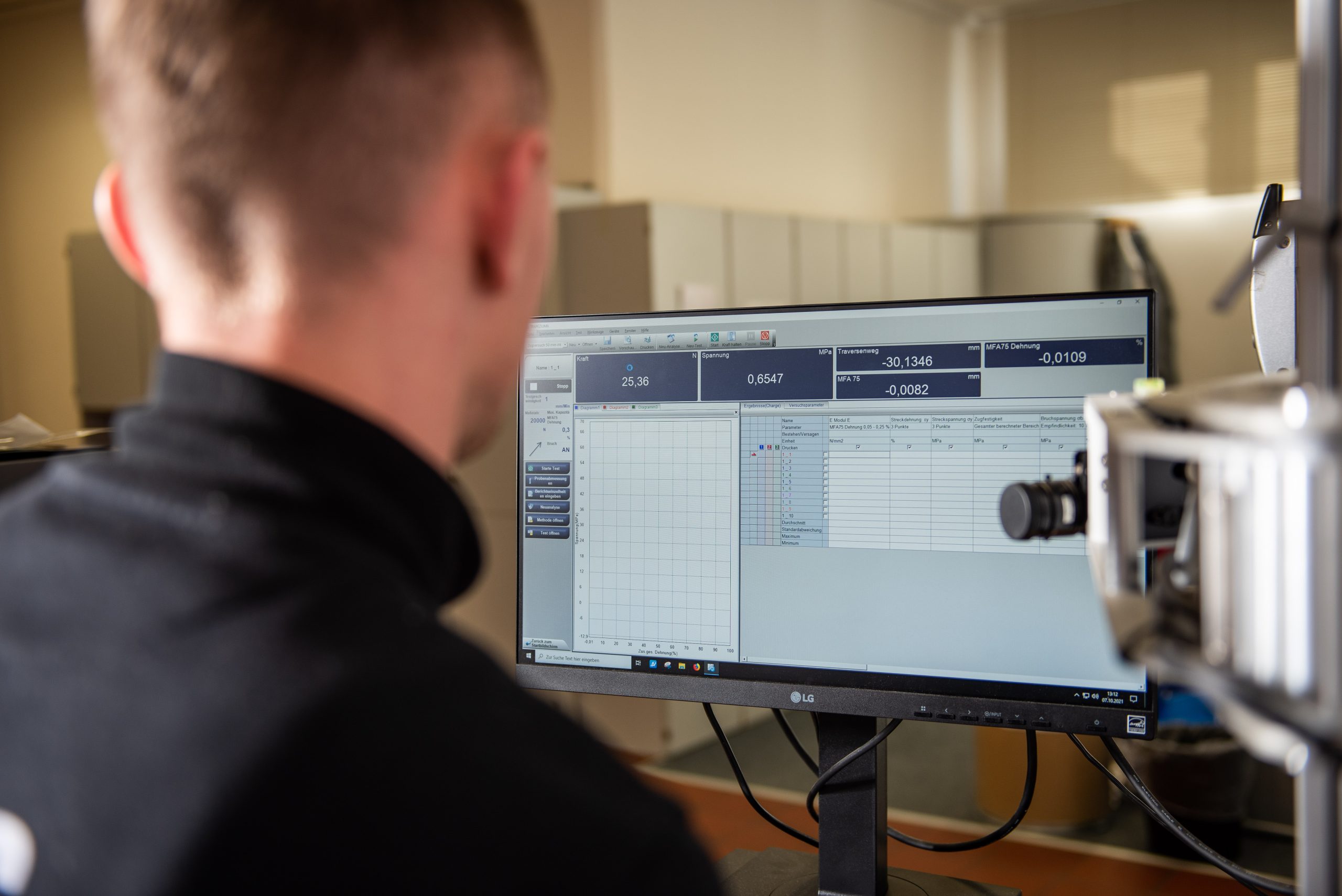

We master a wide range of test methods

Our goal is to get you to your goal quickly and efficiently with our plastics testing services. With our wide-ranging knowledge of engineering plastics, we select together which tests make sense and in which order they should be used to solve your task quickly and cost-effectively. An understandable preparation of the results with practical recommendations for action is, of course, part of our evaluation.

Your advantages at a glance:

The advantages of our test laboratory

Accuracy is our strength – We ensure that you receive your desired test results in a timely manner.

The question of the appropriate test procedure is often complex. We advise you and elicit the appropriate procedure for you.

We have our finger on the pulse of engineering plastics and high-performance polymers for over two decades. With our expertise, you benefit all along the line.

We incorporate our expertise in plastics processing and our wealth of experience in engineering plastics into our consulting and processing services.

Accuracy down to the smallest detail, testing according to DIN, EN, ISO, UL, or other standards e.g. automotive or electrical

You benefit from short internal service routes to our colleagues, e.g. in CAE, application technology, injection molding or toolmaking

We can perform same day testing upon request or quickly and unbureaucratically, perform other or additional testing as needed and appropriate.

Save time and costs by performing tests on test specimens instead of finished components, e.g. 2-component adhesion or chemical resistance.

The cooperation of our individual departments ensures a high degree of speed, effective communication and use of synergies in the implementation of your project.

Test laboratory - From your inquiry to order fulfillment.

Request a quote

Request a quote

Advice on the best course of action

Advice on the best course of action

Quotation preparation within 2 working days

Quotation preparation within 2 working days

Commissioning of the testing laboratory service

Commissioning of the testing laboratory service

We do the job

We do the job

Sending of the meaningful report

Sending of the meaningful report

Satisfied customer - thank you for your trust!

Satisfied customer - thank you for your trust!

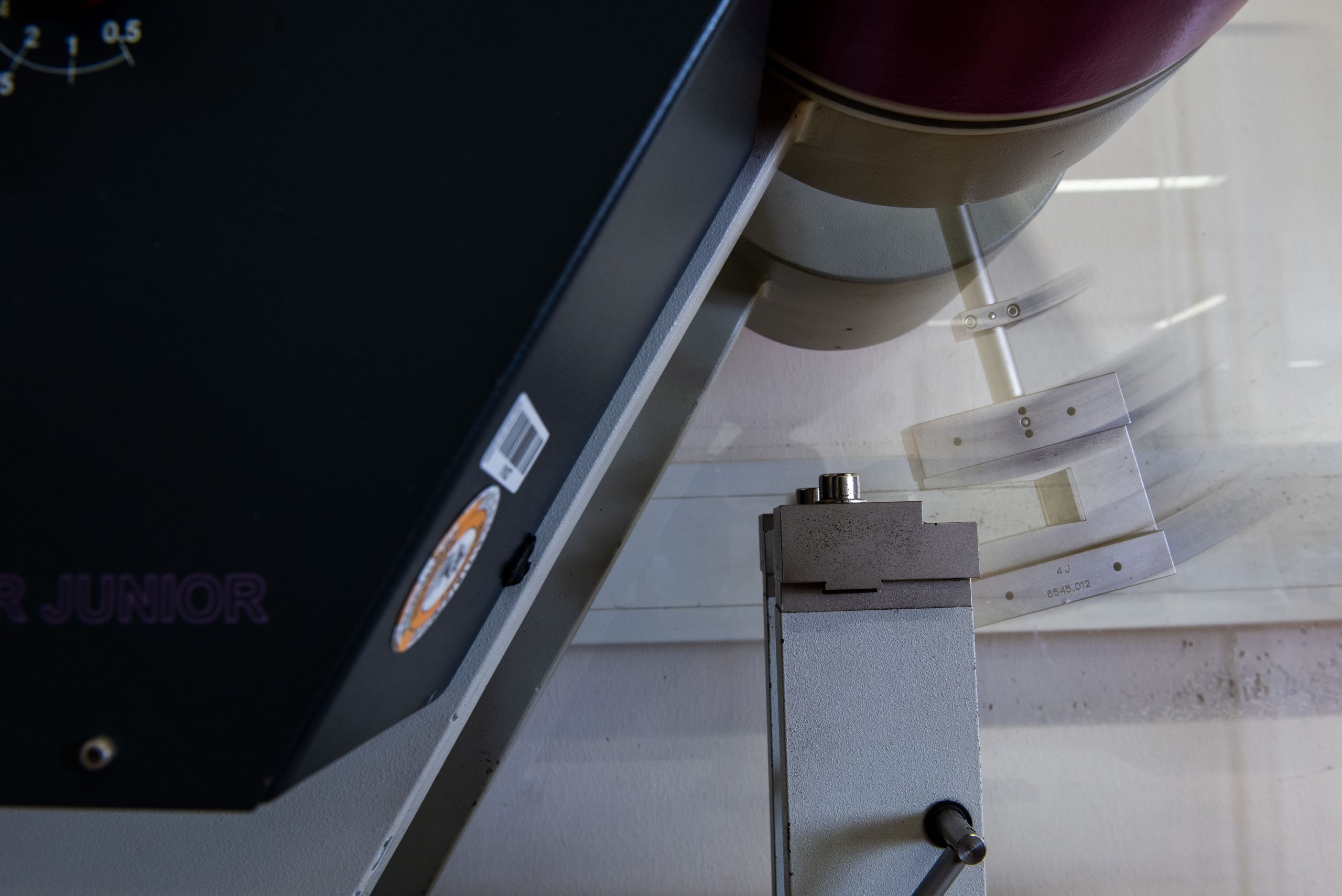

In order to evaluate the properties of a material or product, a variety of characteristic values can be determined depending on the relevant field of application. (…)

Whether for your own testing or one of our services – we offer the “more” in test specimen production in our in-house technical center. (…)

Damage analyses are extremely important, both in the event of a failure at the customer’s site and in the development stage, in order to identify faults and rule them out in the further process. (…)

Material analyses are frequent questions in the development of components. But material analysis can also be helpful in damage analysis. (…)

In order to reduce testing costs and time on the component and at the same time gain certainty in material selection, tests during development are the measure of all things. (…)

For plastics and other materials, there are a number of legal regulations and specifications that material and component manufacturers must comply with. (…)

In our test laboratory, we put your plastic assemblies through their paces as early as the development and prototype stage, helping you to establish even better products on the market even faster(…)

In this section you will find further information on testing procedures that the BARLOG test laboratory can offer you. (…)

about our services?

Then do not hesitate to contact us. Together we will

take a look at your request and will be happy to advise you.

Everything you need to know.

Here you can find more information about our products.

Determination of mechanical, physical and thermal parameters for your project

In order to evaluate the properties of a material or product, a variety of characteristic values can be determined depending on the relevant field of application. In addition to the determination of the characteristic values, we also offer advice on the selection of suitable tests if required. Our spectrum includes general and mechanical characteristic values, as they appear in every data sheet. But also special tests, e.g. with magnetic or electrical requirements, as well as thermal characteristic values are among our possibilities.

We offer a variety of tests for different tasks such as:

New product developments: Does the product meet the expected properties?

Comparison of different variants and preparation of a data sheet

Material selection

Comparison of different materials and batches, testing of special properties not included in the data sheet

Determination of measured data for CAE services:

Determination of characteristic values / material cards according to customer requirements, custom-fit solutions through consultation with our CAE department

If the required test is not listed, please do not hesitate to contact us.

Quality assurance and acceptance test certificates

To perform consistently good work requires a functioning quality management. This often starts with an incoming goods inspection on the granulate. The correct consideration of the relevant standards (DIN, ASTM, …), the comparison of data sheets and factory test certificates as well as the comparability between different materials can be quite challenging.

We offer you a fast, independent verification of test certificates for your material. This includes the determination of measured values of a specific batch and a documented reproducibility. We will be happy to advise you in detail on your question.

Setting up the mold and producing test specimens – the standards

Whether for your own testing or one of our services – we offer the “more” in test specimen production in our in-house technical center. We manufacture test specimens from almost all common thermoplastics. As a rule, all injection-moldable thermoplastics can be processed, including high-temperature materials such as PPS, PEEK, PEK, etc. Our range of services also includes the processing of carbon fiber or glass fiber reinforced as well as filled plastics.

In addition to standard specimens such as the multi-purpose specimen 1A, we also manufacture a wide variety of plates or special specimens such as toroidal specimens, shrinkage plates or 2C test plates. We are able to cover different fields of application such as mechanical, magnetic, thermal and general physical tests with our specimens. You will find a complete overview in our catalog.

Fancy ideas and not the right tool? – We can build your tool

The right test specimen was not yet included? Talk to us!

With our rapid prototyping or injection molding prototypes, we can also implement unusual or novel test specimen concepts.

- Printed test specimens can give a first impression or be used for simple tests. In most cases, however, the properties of an injection molded specimen cannot be achieved.

- For very specific tests, such as shear tests on organic sheets, new tools can be designed and manufactured. Thus, even complex development projects can be implemented.

Damage analyses are extremely important, both in the event of a failure at the customer’s site and in the development stage, in order to identify faults and rule them out in the further process. Determining the cause is therefore always a high priority. For damage analyses, it is important to learn as much as possible about the failure of the component. This includes, for example, forces acting, ambient climate, type and duration of exposure to media, installation situations, regularity of occurrence of the damage, material batches, design changes to the component and much more. Not all information is always available, but the more one knows, the better the procedure for the investigation can be narrowed down and the more target-oriented the damage analysis can be carried out. The type and sequence of methods used depends on the individual case. A wide variety of microscopic methods such as stereomicroscope, SEM, microsections and thin sections are frequently used. But also methods for material identification (material analysis) or other analytical methods for material damage are helpful in many cases for the root cause analysis.

Material analyses are frequent questions in the development of components. But material analysis can also be helpful in damage analysis.

The most important information, such as the polymer used and the type and amount of inorganic filler used, can be determined relatively quickly and inexpensively.

Frequently used in these cases are methods such as DSC analysis to determine characteristic temperatures such as glass transition and melting point of the polymer, IR spectrum for supplementary structure elucidation, determination of the annealing residue to determine the filler used and, if necessary, XRF or EDX analysis for further analysis of fillers.

If the details of additives such as flame retardants, stabilizers or processing aids are to be determined, the methods are manifold and can only be selected after the polymer has been identified.

Depending on the proportion of additives, it is extremely difficult and costly, if not impossible, to determine the type and quantity of additives. The procedure and the benefit of such an analysis must be weighed up in each individual case.

In order to reduce testing costs and time on the component and at the same time gain certainty in material selection, tests during development are the measure of all things. To this end, we produce injection-molded test specimens from the selected materials in advance and test them for their properties. The selection of test methods is precisely matched to the application of the component. For example, the resistance to special chemicals can be precisely tested under certain conditions, or specific statements can be made about the influence of additives, colors or certain processing parameters on mechanical properties. Through application-oriented laboratory tests, we can support you in your material selection right at the start of development.

For plastics and other materials, there are a number of legal regulations and specifications that material and component manufacturers must comply with. In addition to critical ingredients, which are regulated, for example, in the Reach Regulation (No. 1907/2006) or the RoHs Directive (2011/65/EU), there are also regulations on ingredients and migration values for materials that come into contact with drinking water and food. Regulation 1935/2004 is an overarching EU regulation governing materials and articles intended to come into contact with food. Regulation 10/2011 is an individual regulation derived from this, which lays down specific regulations for plastics. This regulation governs which substances may be used in the manufacture of plastics intended to come into contact with foodstuffs, how the manufactured components must be tested and which limit values (=(specific) migration values) must not be exceeded.

In the drinking water sector, there is also the KTW guideline of the Federal Environment Agency, which describes tests for components in contact with drinking water and also defines limits. Furthermore, components in contact with drinking water are tested for their suitability for microbial growth in accordance with DVGW Worksheet W270.

Other countries, other customs… and laws: For the USA, France, Great Britain other laws apply depending on the case. If you need support in the jungle of KTW, FDA, NSF, WRAS, etc., please contact us.

Your BARLOG – Testing Laboratory Team

In our test laboratory, we put your plastic assemblies through their paces as early as the development and prototype stage, helping you to establish even better products on the market even faster. The usability tests are carried out, for example, in the form of strength tests and durability tests perfectly tailored to your product. We discuss the individual test scenarios with you in advance and test your component on the endurance test bench. We provide you with suggestions for optimizing the material, geometry and manufacturing process and also test their effectiveness.

In this section you will find further information on test methods that the BARLOG test laboratory offers for you. By clicking on the links below, you will find a brief description of the test methods listed, including a reference to the respective test standard. The list is only an excerpt of the total offer and is regularly supplemented – so it is worthwhile to check back here from time to time.

If you have an inquiry about a test method that is not listed here, please do not hesitate to contact us. You will find our contact details on the right-hand side.

Do you have

questions about our

products or services?

Then make an appointment with us.

Our team will be happy to advise you in a

personal conversation or by e-mail.