Trade names: KEBAFORM® and KOCETAL®.

Our product range

Our range of thermoplastics is divided into our own compounds and equally high-quality distribution products from the companies EMS Grivory and KOLON ENP, Inc. This carefully selected range, which has been tried and tested in practice, results in a product selection with countless application possibilities and product properties, which we supplement with our numerous services for your product.

Get an overview of the materials available from us. Our technically and commercially experienced contact persons will be happy to answer any questions you may have about product properties and individual offers.

Trade name: KEBATER®

Trade name: KEBATRON

Trade name: KEBAFLOW

Trade names: Grilon and Grilamid

Trade name: Grivory

Trade name: KEBAPEAK

Trade name: KEBAFLEX

Trade name: KEBALLOY

Trade name: KEBABLEND / RS

Trade name: KEBABLEND / H

Trade name: KEBABLEND / EC

Trade names KEBABLEND / M and KEBABLEND / MW

Trade name: KEBALLOY 3D

Trade name: KEBALLOY ECO

Trade name: KEBABLEND / WR

Trade name: KEBABLEND / TC

Trade names: KEBABLEND

Here you can find more information about our products.

Here you can find more information about our products.

POM belongs to the engineering thermoplastics and is characterized by its high dimensional stability, low coefficients of friction and high stiffness.

As a result, it is preferred for use in the automotive industry and electrical engineering.

- unreinforced

- reinforced 10 – 30 %

- Hot diesel resistant

- impact modified

- slip modified

- electrically conductive

- emission-reduced

PBT is a thermoplastic material characterized by its high rigidity, strength and excellent dimensional stability. This material is used primarily in electrical engineering and vehicle construction.

- unreinforced

- reinforced 10 – 50%

- flame retardant UL 94-V0

- PBT-blends

Polyamides belong to the engineering thermoplastics and are characterized by their high toughness and good sliding properties. They are excellently suited for use as metal substitutes, where their high mechanical strength is impressive.

PA 6, PA 66, PA 66 + PA 6, PA 12, amorphes PA

PPA is one of the high-performance polyamides and is particularly impressive due to its extreme heat resistance and mechanical strength.

PPA is used in the automotive industry for gasoline and cooling lines.

PPA-Blends, HT-PPA

PPS is a thermoplastic and offers very high chemical resistance and stiffness. Thanks to its outstanding properties, PPS is used in components subject to high mechanical, electrical, thermal and chemical stresses in the automotive and electronics sectors.

- linear and networked

- reinforced 40% – 65%

LCP are liquid crystalline polymers that are characterized by their dimensional stability and chemical resistance at high temperatures. Their field of application is primarily in mechanical and vehicle engineering as well as in the electrical industry.

- HDT 270°C und 300°C

- glass fibre reinforced

- hybrid reinforced

PEEK is a high-temperature-resistant thermoplastic that is characterized by its very high chemical resistance. Its main applications are in the automotive industry and as an insulating material in high-voltage engineering.

- unreinforced

- glass fibre reinforced

- carbon fiber reinforced

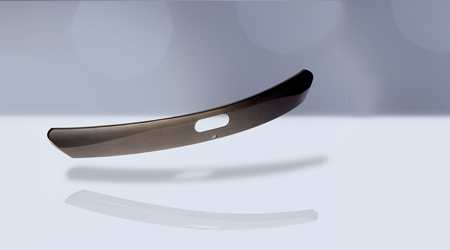

PC/ABS is convincing due to the combination of the good processability of ABS and the excellent mechanical properties of PC.

This material is used primarily in automotive interiors.

- Galvanotype

- unreinforced

TPEs are thermoplastic elastomers that can be deformed by heating. They are as soft as rubber and are used in a wide variety of applications.

TPE-S: SEBS – Compounds

- Shore A 10 – D 55

- adhesion modified, hard/soft

- filled and unfilled

TPE-V: EPDM/PP – Compounds

- Shore A 35 – D 50

- low-emission

KEBABLEND / RS are products that can be used for radiation protection.

We develop customized KEBABLEND / RS products based on the following polymers:

- EBA

- PA 12

- PPS

- PPA

KEBABLEND / H is the name of our heavy materials that can be injection molded into high-density parts. Kebablend / H is based on a wide variety of polymers with heavy filler combinations. However, restrictions on the volume concentration depending on the desired polymer must be observed.

We develop customized KEBABLEND / H products based on the following polymers:

- EBA

- PA 12

- PPS

- PPA

KEBABLEND / EC – electrically conductive compounds

Under the trade name KEBABLEND / EC, BARLOG Plastics GmbH markets a range of plastics with electrically conductive fillers, for the manufacture of components with good electrical properties. From antistatic behavior to good electrical conductivity and shielding properties, this product group offers a lightweight alternative to metals with a high degree of design freedom. Typical applications of KEBABLEND / EC are housings in automobiles with minimal weight for the shielding of electromagnetic fields or conductive components in the field of electrical engineering.

Why KEBABLEND / EC?

- up to 50% lighter than aluminum

- Cost reduction of the overall system

- Design freedom in the injection molding process

- EMC-compatible component design

- Possibility of function integration

KEBABLEND / EC electrically conductive compounds are generally tailor-made for specific customers and applications. The choice of base polymer for the electrically conductive fillers and other fillers and reinforcing materials is made in close consultation with our customers’ development engineers.

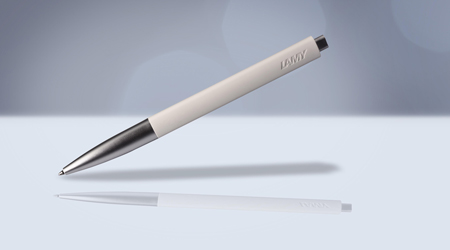

KEBALLOY 3D

Preferences:

Designed for painting plastic parts with a 3 dimensional effect.

- Maximum individualization

Flexible designs, up to quantity 1

- Suitable for production even for large series

No additional effort for tooling and setup costs or logistics costs

- Detailed contours and logos

Through magnetism, the necessary information is stored in the surface of the component

Special features:

- Patented system of material and process engineering

- Extrudable and injection moldable plastic compounds with magnetic filler particles

- Insertion of the magnetic pattern by writing with a magnetic pen or stamp

- 2 layer system (base coat + clear coat)

- Plastics such as ABS, PC and PC/ABS can be painted without primer, others such as PA6 or PBT require a primer or undercoat.

Cost analyses by German automakers have confirmed:

Components with KEBALLOY 3D effect coatings from BARLOG bring a clear advantage in the competition with today’s common, foil-backed design elements in the cost-benefit comparison due to their enthusiasm factors!

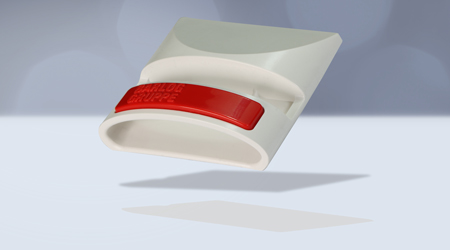

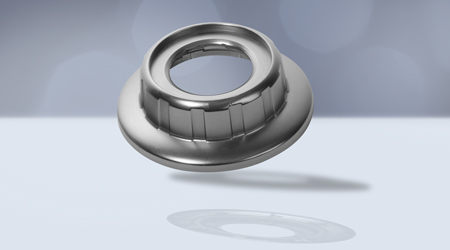

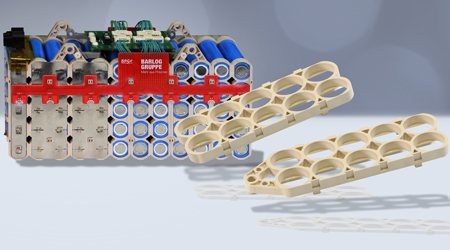

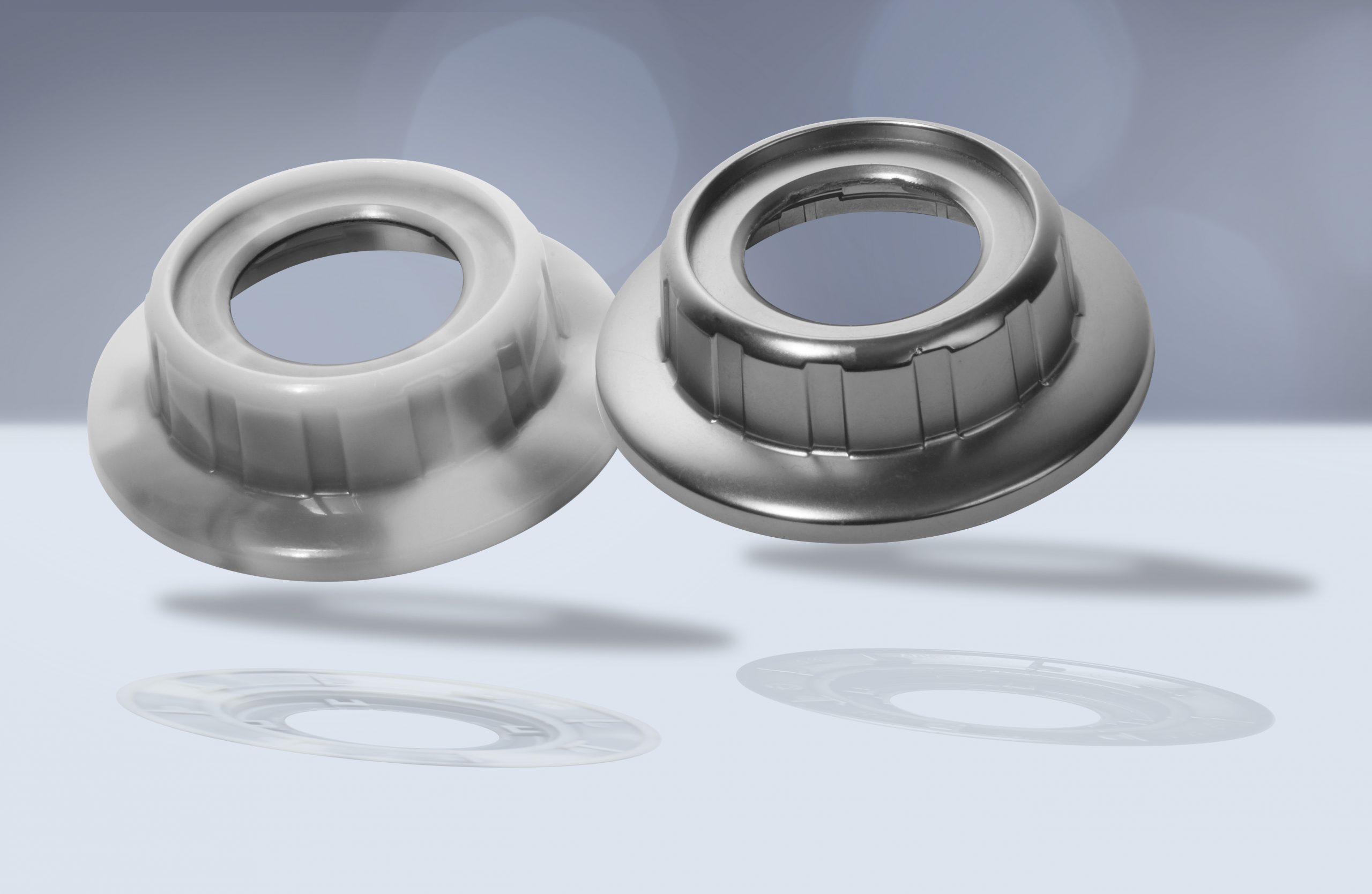

KEBABLEND / M and MW – Magnetic materials for the production of injection molded magnets

Under the trade name KEBABLEND / M and MW BARLOG Plastics GmbH sells functional compounds for the production of injection molded magnets as well as soft magnetic components.

Why KEBABLEND / M?

- Hard magnetic

- Can be magnetized in the injection molding process (inmold magnetizing)

- High remanence and coercivity

- High design freedom

- good toughness and strength

- media resistant

Why KEBABLEND / MW?

- Soft magnetic

- High permeability

- Optimally suited for shielding or magnetic field guidance

- High design freedom

- good toughness and strength

- media resistant

KEBALLOY ECO – Recycling Compounds

BARLOG Plastics GmbH markets recycling compounds under the trade name KEBALLOY ECO.

Why KEBALLOY ECO?

- Food contact applications possible (PET)

- Selected recyclates from stable raw material sources – Post Consumer and Post Industrial

- High quality standards with specification of material characteristics

- Customized recipes adjustable

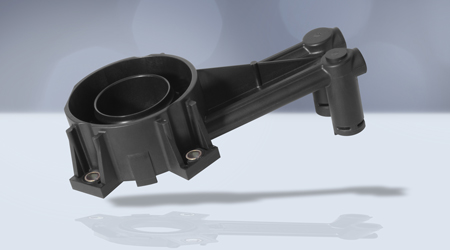

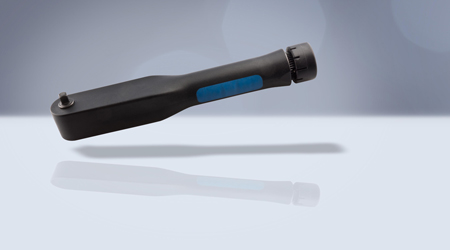

KEBABLEND / WR – Tribological compounds

Under the trade name KEBABLEND / WR, BARLOG Plastics GmbH markets tribologically optimized compounds for moving components, such as plain bearings, gears, rollers, sliders in countless applications. Incorporated lubricants and reinforcing materials improve the wear, friction and running-in behavior of polymers and thus of the tribological system. This results in maintenance-free or low-maintenance systems that function without additional lubrication. In lubricated assemblies, the emergency running properties of these materials come into play, thus increasing safety for the designer and the user.

Why KEBABLEND / WR?

- Improved sliding and wear behavior compared to unmodified plastics

- Maintenance-free or low-maintenance systems

- No additional lubrication necessary

- Tailor-made for your requirements

- Wide range of products as standard assortment

KEBABLEND / WR tribologically modified compounds can basically be adjusted on the basis of all engineering plastics and modified to suit the respective application by using lubricants such as PTFE, MoS2, graphite and silicone oil, as well as wear-reducing and reinforcing additives such as carbon, glass and aramid fibers, mineral or ceramic.

KEBABLEND / TC – thermally conductive compounds

Under the trade name KEBABLEND / TC, BARLOG Plastics GmbH markets a range of thermally conductive plastics for the manufacture of components in all areas of application that require thermal management, e.g. in the cooling of electrical and electronic components or the heating of fluid lines. KEBABLEND / TC is used in automotive applications, LED technology, photovoltaic components and in all other areas where thermal management plays a role.

Why KEBABLEND / TC?

- up to 50% lighter than aluminum

- Cost reduction of the overall system

- Design freedom in the injection molding process

- Possibility of function integration

- Electrically insulating types available

Due to the wide range of requirements in thermal management, KEBABLEND / TC thermally conductive compounds are usually tailor-made to meet specific customer and application needs. The choice of base polymer, thermally conductive fillers and other fillers and reinforcing materials is made in close consultation with our customers’ development engineers.

Do you have

questions about our

products or services?

Then make an appointment with us.

Our team will be happy to advise you in a

personal conversation or by e-mail.