What our customers say

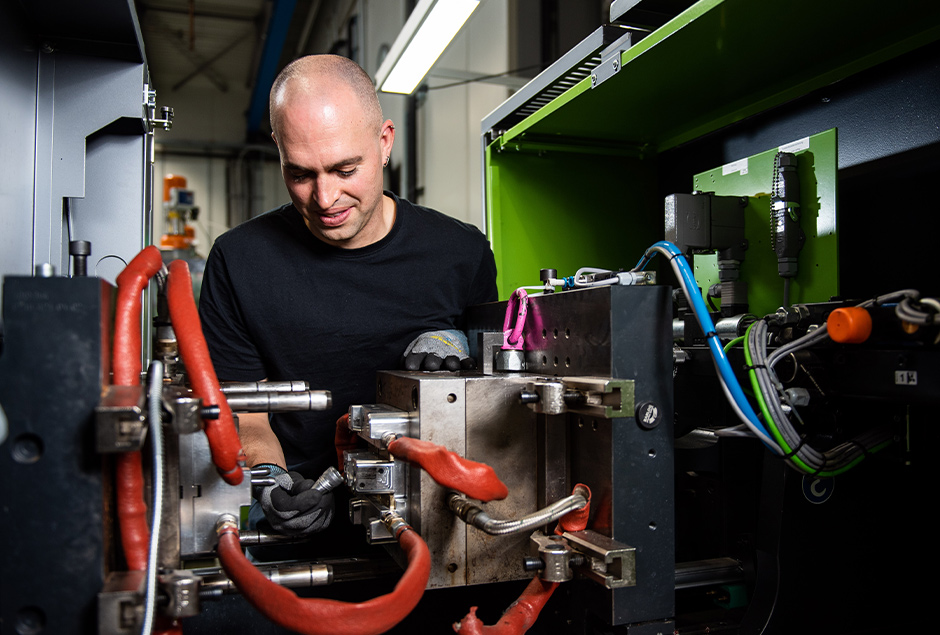

Plastic injection molding prototypes

Our protosys® business unit specializes in the production of high-quality prototypes made of plastic. We process all thermoplastics from PE to PEEK, thermoplastic elastomers and liquid silicone (LSR).

The use of the Rapid Tooling process enables us to provide you with prototypes of optimum quality in the shortest possible time. By using aluminum mold inserts and flexible master mold concepts, we can extremely reduce machining times and tooling costs compared to steel molds.

Our extensive machinery is at your disposal for the production of your components. In addition to our standard injection molding machines (clamping force between 6 to – 450 to) and our 2K machine (clamping force 50 to), we even offer you a vertical injection molding machine (clamping force 50 to) for the production of plastic-metal composite parts.

Put your project in the fast lane and contact us!

Your advantages at a glance:

The advantages of our injection molded prototype

Plastic prototypes

With the rapid tooling process, we achieve maximum quality for your prototypes.

Thanks to the rapid tooling process, we create high-quality prototypes in the shortest possible time.

We use aluminum for tooling production and thus keep tooling costs very low.

Aluminum mold inserts & flexible master mold concepts save time and provide the necessary tooling for your prototyping needs.

We process all thermoplastics. Starting with standard plastics (e.g. PE), through technical thermoplastics (e.g. PBT / PA) to high-performance plastics (e.g. PEEK) and even LSR – liquid silicone. The material application possibilities are manifold.

Quality standards that also inspire our customers. Our high-quality and near-series prototypes are produced quickly and cost-effectively.

Whether standard injection molding, multi-component injection molding, sandwich injection molding, foaming, silicone injection molding, in-mold labeling, gas injection technology or the overmolding of metal inserts – our process is tailored to your requirements.

We are happy to offer laser marking, ultrasonic welding and component assembly for further processing of your components.

Reliability is a top priority for us. We always meet promised deadlines and thus offer you the highest degree of planning security.

Injection molding prototypes - From your inquiry to order fulfillment.

Request a quote and upload data

Request a quote and upload data

Quotation preparation within 2 working days

Quotation preparation within 2 working days

Commissioning of prototype production

Commissioning of prototype production

Definition of the quality characteristics

Definition of the quality characteristics

Prototype production

Prototype production

Satisfied customer - thank you for your trust!

Satisfied customer - thank you for your trust!

Rapid tooling is primarily about producing a functional prototype as quickly and cost-effectively as possible using injection molding.(…)

Plastics are very versatile materials and offer product developers a wide range of material properties to produce high-quality components at low cost.

The protosys® services from BARLOG Plastics can now be used in the development phase with fully functional components made of LSR series material.(…)

The vertical injection moulding machine can produce a wide range of plastic-metal composite parts (hybrid components) with high accuracy and precision.(…)

about our services?

Then do not hesitate to contact us. Together we will

take a look at your request and will be happy to advise you.

Our application examples

Everything you need to know.

Here you can find more information about our products.

Rapid tooling is primarily about producing a functional prototype as quickly and cost-effectively as possible using injection molding.

In order to be able to offer our customers these advantages, we do not build complete molds in the rapid tooling process but mold inserts for our master molds. These consist of two molding halves, with or without slides, and the ejector. Our master mold, together with the mold insert produced for you, then forms a functional injection mold.

The mold inserts are usually made of aluminum. This material combines good machinability with an excellent service life for prototypes and small series.

Depending on the plastic processed, quantities of up to 30,000 units per cavity can be produced with the aid of a special anti-wear coating.

Plastics are very versatile materials and offer product developers a wide range of material properties for producing high-quality components at low cost. In particular, the possibilities for saving components through function integration offer considerable potential. Frequently, however, the various functions that a product is supposed to have are so different that one material alone cannot fulfill them.

In order to nevertheless keep the number of necessary components as low as possible and save assembly processes, multi-component injection molding is a manufacturing process in which a component is made from several materials in a single production step.

For example, high-strength housings with integrated, flexible seals or tool handles with soft haptic components can be produced. An example of multicomponent injection molding that everyone is familiar with from everyday use is toothbrushes – here, 5 or more different materials are often combined in a single production step to create a final product.

In order to achieve an inseparable connection between two materials, there are two different possibilities:

Positive-locking connections

Undercuts or openings are made in the geometry of the first component (usually the hard component in hard/soft composites), which are then filled with the second (soft) component. This creates a mechanical interlock and thus also allows chemically incompatible materials to be combined.

Material bonded joints

Materials are used that exhibit chemical-physical adhesion to each other during injection molding. This is achieved either by using related materials (e.g. PP with TPE-S) or by modifying one of the two materials with a suitable adhesion promoter.

Here you benefit from the interaction of BARLOG Plastics, because we offer an extensive range of adhesion-modified plastics and has many years of experience in the modification of materials for 2C injection molding, so that we can provide you with competent advice on the production of prototypes and small series from the idea to the series from a single source.

Multicomponent injection molding for prototypes and small batches

Since the production of multi-component injection molded parts is usually associated with high tooling costs, this technology has so far mainly been used for large quantities. Our protosys business unit has many years of experience in multi-component injection molding and also offers the possibilities of this technology in the rapid tooling process for the production of injection-molded prototypes or even for the realization of your small series production.

Such components are of course not realized fully automatically in our rapid tooling process, as in large-scale production, but semi-automatically. The hard component is injected in a cavity and this is then manually inserted into the cavity of the soft component and overmolded.

The particular challenge in the 2C process is that the cavity of the second component must be adapted to the injection molded part of the first component so that overmolding is avoided.

Sandwich injection molding

The sandwich injection molding process also makes it possible to combine several properties in one injection molded part and achieve functional integration. The special feature of this process is the possibility of achieving a layer structure with a closed outer skin, e.g. in order to use a decorative material on the outside and a functional material on the inside, largely invisibly. Examples of applications for sandwich injection molding include chrome-plated door actuation levers in automotive interiors or our Carabiner 2.0.

The inner layer of this consists of a carbon fiber reinforced POM (KEBAFORM C904 CF black) to achieve the required strength and rigidity. In order to simultaneously achieve the flexibility and spring action for the hinge function of the snapper without having to mount additional components, the outer skin is made of unreinforced POM (KEBAFORM C90.0 red).

In the sandwich injection molding process, the mold is partially pre-filled with the material that will later be on the outside. The second component is then injected through the same gating point, displacing the still plastic first material and thus forming an inner layer with different properties.

In this way, components are obtained which also fulfill supposedly contradictory requirements, such as strength and flexibility or function and decoration in equal measure.

Did you know?

The sandwich process was originally developed to make low-cost recycled material disappear inconspicuously inside a plastic part. As is so often the case, the inventors did not realize the true potential of their invention until later.

Fast, efficient and close to series production. Prototypes and small series made of LSR / liquid silicone

The protosys® services of BARLOG Plastics can now be worked with fully functional components made of LSR series material already in the development phase. For this purpose, BARLOG Plastics produces an liquid silicone rubber prototype using injection molding from the customer’s virtual 3D CAD component via mold design, including rapid tooling. You benefit directly from near-series experience and results, and do so particularly quickly, cost-effectively and efficiently.

LSR processing: BARLOG Plastics know-how opens up many possibilities

Liquid silicone rubber processing requires sophisticated process engineering, which BARLOG Plastics has optimized for the LSR prototype sector. Due to the low viscosity of LSR, BARLOG Plastics can process the components directly by injection molding using a mixing and metering system. Special units are used on the injection molding machine for this so-called liquid injection molding.

LSR: A material with high potential

– Ideal for short time-to-market processes

– Wide range of applications from consumer products to automotive, sanitary and medical technology

– Special electrical properties (insulating or conductive)

– Consistent mechanical properties over a wide temperature range

– Processing free of split products and reinforcement of the final material properties by on-site annealing possible

– Curing of liquid components in evacuated mold at 140 – 230° C

LSR: Many advantages, many possibilities

– Elasticity

– Temperature resistance

– Weathering resistance

– Oxygen permeability

– Excellent compression set

– Chemical and UV stability

– Biocompatibility

– Easy to color

– Part size 0.25 – 100 cm² projected area

– Shot weight 0.5 – 100 g

With the vertical injection moulding machine, a wide range of plastic-metal composite parts (hybrid components) can be produced with high accuracy and precision. Last but not least, the use of the sliding table enables more repeatable and also faster cycle times in the semi-automatic process, for example with metal inserts. In summary, this type of production offers a more cost-effective, faster and more precise alternative, especially in the medium to high volume range.

A vertical injection moulding machine is able to produce high quality plastic parts at high speed and to overmould metal parts, for example. It has a direct vertical clamping system that eliminates the need for a separate clamping unit. In addition, the vertical orientation enables greater precision in the moulding of complex components compared to conventional injection moulding machines.

We opted for a vertical sliding table ALLROUNDER 375 V 500 – 170 injection moulding machine from ARBURG. This high-performance machine has a clamping force of 500 kN and can produce parts with a shot weight of up to 80 grams. It is suitable for use in a wide range of industries and applications, including the automotive, electronics, medical and consumer goods industries.

Complicated details, such as plastic-metal composite parts, which were only possible to a limited extent with previous injection moulding machines, can thus be produced without any problems.

Based on your 3D component design, we manufacture aluminum mold inserts on our HSC milling machines and fit them into our flexible master mold system. In the rapid tooling process, we mostly produce injection-molded prototypes. However, it is just as suitable for the production of pilot series, as bridge tooling and for the production of small series.

With non-reinforced standard plastics, we can easily offer small series of up to 50,000 units per year over several years. In the case of reinforced plastics, special coatings are used for the mold inserts in order to optimize the service life of the mold inserts and minimize maintenance requirements. In individual cases, however, we also use mold inserts made of steel from the outset in order to be able to guarantee your desired quantities.

The question cannot be answered in such a general way, but as soon as you need near-series components made of original material for real tests, the rapid tooling process is the clear favorite. The advantages: Free material selection, high surface quality (with or without structure) and no compromises in the quality and properties of the material. And already from 10 pieces, rapid tooling can have commercial advantages over 3D printing.

If your component geometry can be manufactured by injection molding, then we can also represent it in the rapid tooling process. We will be happy to advise you on design suitable for production and plastics and verify manufacturability using injection molding simulations in our CAE department.

Thanks to our certified quality management system according to ISO 9001:2015, change management is ensured during the ongoing project. The rapid tooling concept with mold inserts in master molds enables virtually unlimited change grinding of your component geometry, which we realize for you quickly, easily and cost-effectively.

If a plastic can be thermoplastically processed by injection molding, we can also use it for the production of prototypes and small series in the rapid tooling process. Regardless of whether standard plastics such as PE, PP or PS, technical thermoplastics such as PA, PBT or ABS or high-performance plastics such as PPA, PPS or PEEK. The possibilities for material selection are unlimited and even highly filled, fiber-reinforced or slip-optimized plastics are no problem – the full freedom of the injection molding process.

You have full material freedom and can provide us with any plastic for your project. We will also be happy to procure your desired material through our network. But the quickest way is to select one of the more than 200 materials we have in stock at all times. And if you have very special requirements, we will even develop your personal plastic with customized properties.

In addition to standard injection molding on machines from 60 to 4500 kN clamping force, we also offer injection molding prototypes and small series in special processes, such as multi-component injection molding, sandwich injection molding, foaming, silicone injection molding or gas injection technology. Overmolding of metal inserts or inmold labeling are also common injection molding processes. In addition, we also offer further processing of your components, for example by laser marking, ultrasonic welding and component assembly.

protosys® Rapid Tooling is a component of our comprehensive range of engineering services. This ranges from the initial product idea, through material selection, design suitable for plastics, FEA structural analyses, injection molding simulations, laboratory tests and CT scans, to series production. The combination of development services with the material expertise of a compounder is unique. At BARLOG Plastics, you get the complete know-how from material formulation, compounding and product development to the finished plastic part from a single source.

Send us your request via our offer form. There you can also transfer your 3D data securely and encrypted and we guarantee the confidentiality of your data and your request. Our experts will check your request immediately and usually provide you with your personal, free and non-binding offer within one working day after receiving complete request data.

If your company does not allow encrypted data transfer via the Internet, you are welcome to provide us with your 3D data via Odette or TeamBeam. Please feel free to contact us by e-mail or telephone: +49 2206 90851-100

Our vertical injection molding machine is capable of producing high quality plastic parts at high speed and overmolding metal parts, for example. Due to the direct vertical clamping system, no separate clamping unit is required. With a clamping force of 50 tons, it can produce parts with a shot weight of up to 80 grams. Our vertical molding machine is suitable for use in a wide range of industries and applications, including automotive, electronics, medical and consumer goods.

Do you have

questions about our

products or services?

Then make an appointment with us.

Our team will be happy to advise you in a

personal conversation or by e-mail.