What our customers say

We offer the right tools

It is usually a long and cost-intensive development process from the initial idea to the market launch of a product. Even at this stage, it is crucial to determine whether a product will be able to compete successfully on the market in the future. Those who manage to shorten the time to market through effective design are the necessary “nose length” ahead of their competitors. With the modules of our service package “from the idea to series production”, we offer you exactly the right tools here

Your advantages at a glance:

The benefits of our rapid prototyping services

Testing components as early as possible saves costs and shortens the development process. Not all tests can be carried out virtually – sample parts produced at short notice can help here.

In consultation with you, our engineers analyze which manufacturing process or material is suitable for the application, the component and the required quantity.

Our additively manufactured as well as milled prototypes are subject to 100% inspection so that nothing stands in the way of the success of your prototyping phase.

Whether the additive manufacturing processes (FDM, MJM, SLS, SLA), vacuum casting or CNC machined – we perfectly master the wide spectrum of rapid prototyping.

The different manufacturing processes we use result in a wide range of possible materials for the first prototypes.

Reliability is a top priority for us. We always meet promised deadlines and thus offer you the highest degree of planning security.

The combination of development services with the material expertise of a compounder is unique to us. You get the complete know-how from the material formulation, compounding and product development to the finished plastic component from a single source – we offer “more from polymer”.

We have been a reliable and experienced partner since 1996 – we offer customized service with extensive project know-how from more than 25 years of company history.

All our departments are networked with each other and are in constant exchange. These synergies ensure a high degree of speed and effective communication in the implementation of your project.

Rapid Prototyping - From your inquiry to order fulfillment.

Request a quote and upload data

Request a quote and upload data

Advice on the material and manufacturing process

Advice on the material and manufacturing process

Quotation preparation within 2 working days

Quotation preparation within 2 working days

Commissioning of rapid prototyping

Commissioning of rapid prototyping

Our Doing - Production of the prototypes

Our Doing - Production of the prototypes

Satisfied customer - thank you for your trust!

Satisfied customer - thank you for your trust!

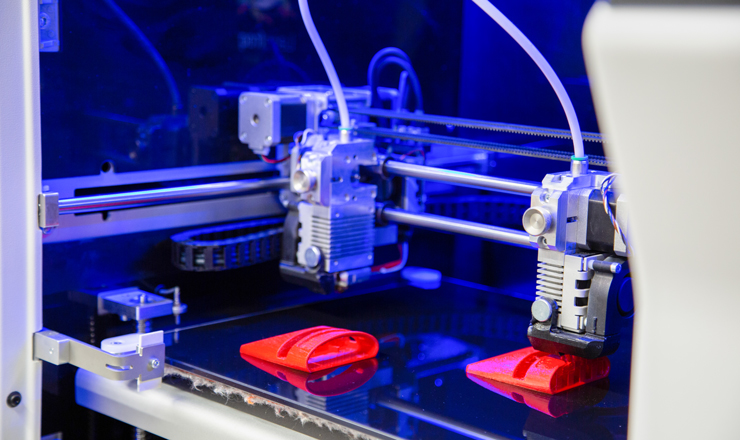

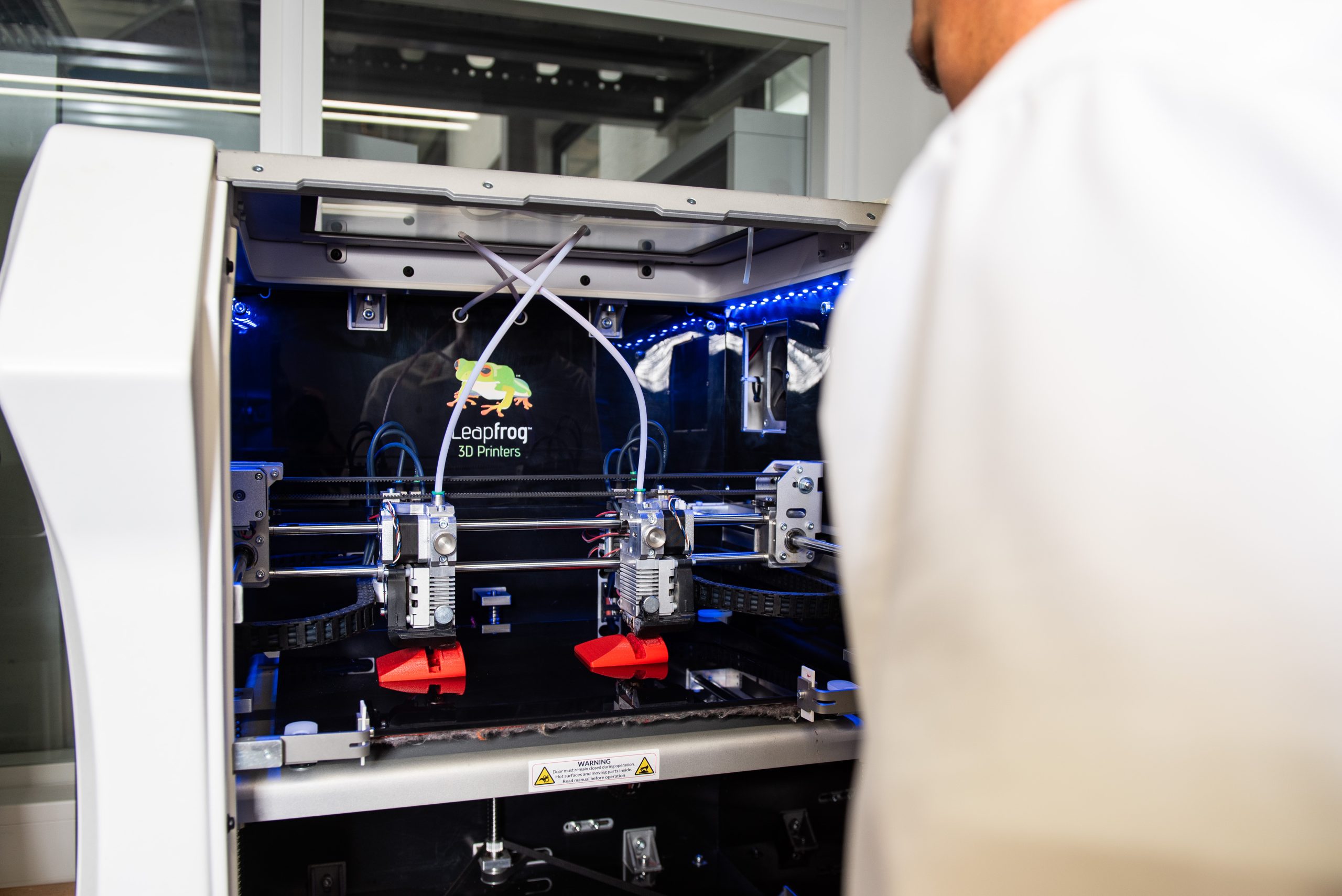

FFF processes are all those in which a thermoplastic filament is melted and extruded through a fine nozzle. (…)

Similar in operation to a conventional inkjet printer, a liquid acrylic photopolymer is sprayed through fine nozzles onto a substrate in a contour-faithful manner. (…)

In laser sintering, a powdered thermoplastic is bonded layer by layer by a laser beam. (…)

In stereolithography, the models are created with the help of a laser. (…)

about our services?

Then do not hesitate to contact us. Together we will

take a look at your request and will be happy to advise you.

Everything you need to know.

Here you can find more information about our products.

FFF processes are all those in which a thermoplastic filament is melted and extruded through a fine nozzle. The contours of the models are created by depositing the fine plastic strands out of the nozzle in a defined manner.

The whole-surface layers are then created by folding the individual strands of material together, the piling up of which leads to the creation of the parts. Often, the models are created with internal support structures, which

are often created with internal support structures, which means that the mechanical properties of the models may differ somewhat from those in injection molding.

Materials:

Thermoplastics (ABS, PLA, PET, PA, TPE and many others).

If you have special tasks, it is possible to develop special functionalized 3D printing materials for you with our material experts.

Similar in function to a conventional inkjet printer, a liquid acrylic photopolymer is sprayed through fine nozzles onto a substrate, true to contour. A rotating UV lamp then cures the

the still liquid material directly. Here, too, the finished component is created layer by layer.

Support structures are generated automatically by a second nozzle. The waxy support material can be easily removed after the manufacturing process using a water jet. The process offers the advantage of a (partially) smooth surface.

Due to the high temperature resistance of the crosslinked photopolymer, the MJM process is particularly suitable for the fast and cost-effective production of mold inserts for rapid tooling.

In laser sintering, a powdered thermoplastic is bonded layer by layer by means of a laser beam. The laser precisely traces the model contour of a layer and melts the individual plastic grains together. After each layer has been produced, the build platform lowers by the height of a layer thickness (a few tenths of a millimeter). A pusher then distributes new material so that the laser can trace the contour of the next layer and melt it together. In this way, the desired model is created layer by layer. Built solid, the properties of the printed models are close to those of the later end products.

Resulting from the powdery base material, laser sintering produces matte surfaces that can be reworked if necessary.

Materials:

Thermoplastics (PA, PA GK, TPE).

In stereolithography, the models are created with the aid of a laser. Similar to laser sintering, the raw material, in this case a liquid resin, is bonded by the focused light beam. The laser traces the contour

of each individual layer of the component, crosslinking the material in the process. Once a layer is completely created, the platform lowers and the next layer is created. On the one hand, the liquid material offers the advantage of producing very filigree components. However, because of the liquid, support structures such as those used in multi-jet modeling must also be built underneath in some cases, and these must then be removed manually.

It is usually a long and cost-intensive development process from the initial idea to the market launch of a product. Even at this stage, it is crucial to determine whether a product will be able to compete successfully on the market in the future. Those who manage to shorten the time to market through effective design are the necessary “nose length” ahead of their competitors. With the modules of our service package “from the idea to series production”, we offer you exactly the right tools here.

One of these is our protosys® Rapid Prototyping. Hereby we enable you to hold your first sample in your hand already in your planning phase in a simple way and within a very short time and to use it as a decision-making aid for the further process.

Do you have

questions about our

products or services?

Then make an appointment with us.

Our team will be happy to advise you in a

personal conversation or by e-mail.