Best Practice: Metrology – The right way to the digital twin

Quality assurance through 3D coordinate measuring technology is an integral part of the development and production process. Tactile coordinate measuring machines are usually used to check the requirements. As an alternative, optical, digitizing measuring methods, such as fringe light projection or computer tomography, have been available for some years. But which method is the right one for my application? What advantages do these new methods offer me over the proven tactile technology?

The advantages of digital measuring methods

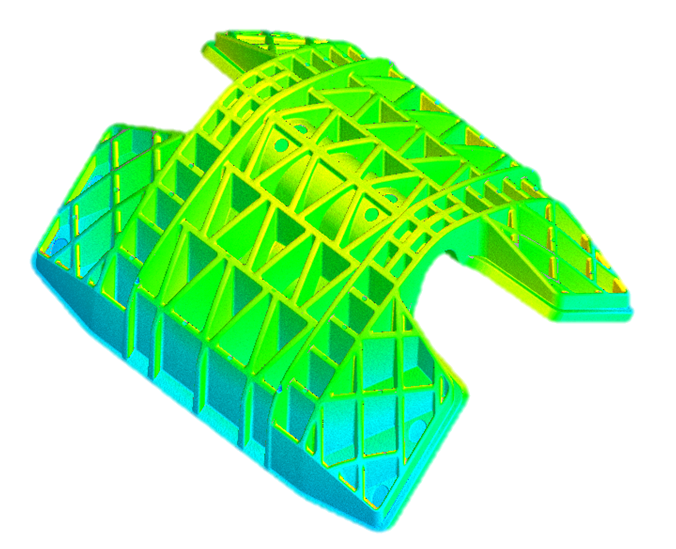

The first clear difference between computed tomography (CT) and fringe light projection compared to tactile measurement is the full-surface digitization of the components. The result of the methods is an STL file, the so-called optical digital twin of the component, which represents all geometric information of the real component. The subsequent measurements are contactless and virtual. This not only eliminates the need for machine processes, which in turn results in shorter runtimes for the individual measurements, but also means that no probing forces are required. This means that flexible materials such as silicone and TPE can also be measured reliably. Virtual probing also allows components with a large number of points to be measured without a great loss of time. “This advantage is of great importance because, taking into account increasingly complex geometries, free-form surfaces can also be recorded holistically and precise statements on form deviations can be made,” says Lukas Tautz, B. Eng. for the Metrology division at BARLOG Plastics.

In the CT, the sample is first placed on a rotatable device between an X-ray source and a detector. Then, several thousand two-dimensional images of the component are taken from all spatial directions, which in turn are assembled by computer to form a 3D model – the optical digital twin. In contrast to the other methods, the components are completely irradiated in the CT. This allows undercut areas to be reliably measured and specific insights into the interior of the component to be created – and this in a non-destructive manner. This serves, among other things, to detect defects, air inclusions, foreign materials and closer examination of fiber distribution.

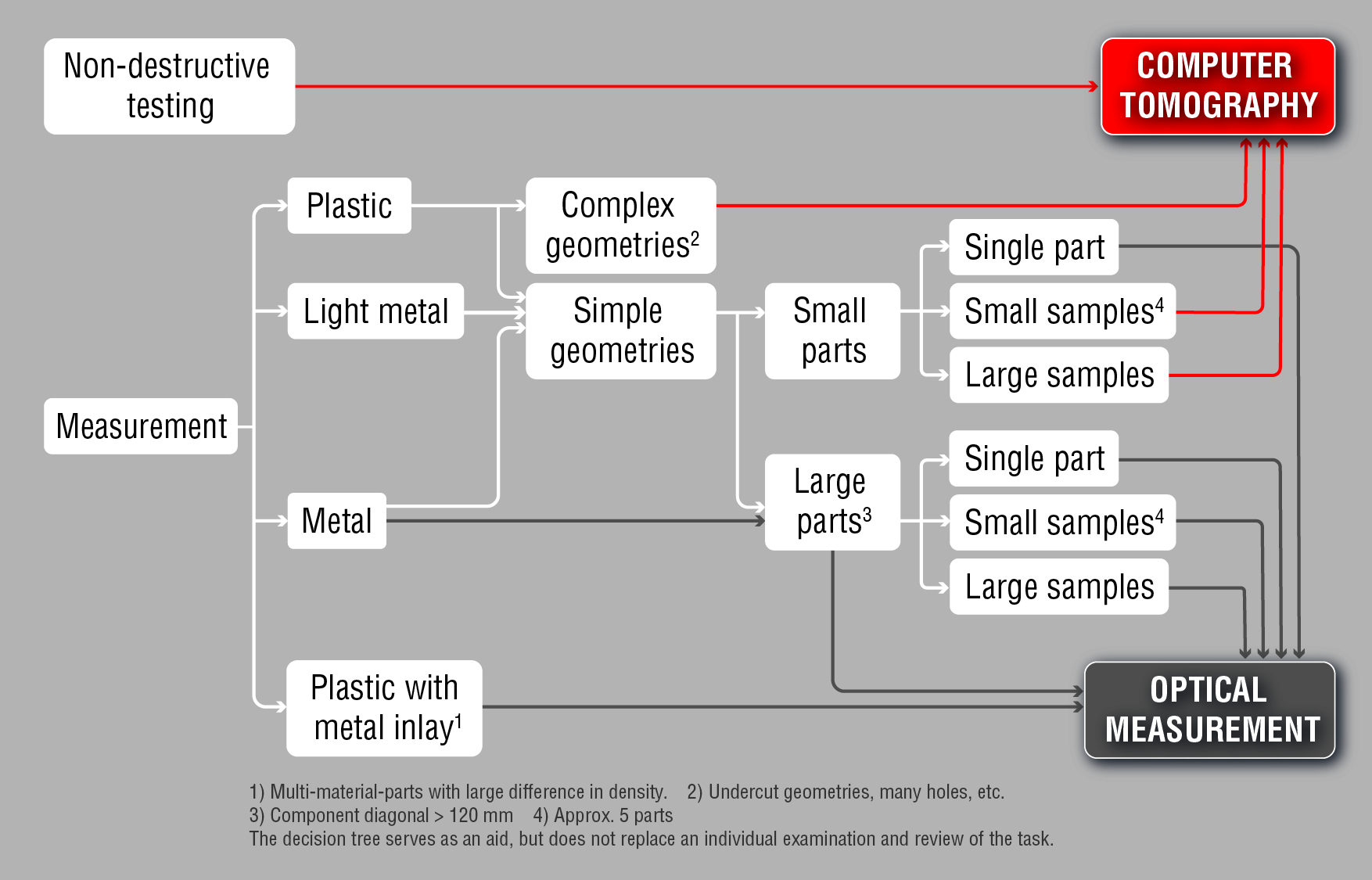

While CT has now become almost without alternative for plastic parts due to the possibilities of seamless and parallel digitization of several components, it reaches its technical limits for very dense materials, but especially for multi-material components (plastic + metal). In this case, the differences in density lead to so-called artifact formation, which makes a clean determination of the surface impossible and thus also does not allow measurement.

The fringe light projection as an alternative

In this case, optical measurement by means of fringe light projection can be used. Here, a stripe-shaped light pattern is projected onto the test object, which is curved differently depending on the component contour. This curvature is then recorded by a camera using a large number of images and reconstructed by a computer to form a three-dimensional point cloud. In contrast to CT, there are basically no restrictions on the materials used in this procedure. Only transparent components and highly reflective or very dark surfaces must first be matted with an extremely thin layer of chalk spray.

The measuring device is freely movable and not in a closed measuring chamber as in CT, so that even very large components can be digitized effortlessly. The process experiences limitations with very complex undercut geometries or deep bores, as the camera’s field of view cannot capture these.

Selecting the right measuring method

If the technical requirements of the task allow both methods to be selected, it often remains a purely economic decision. For example, several small components can be captured in parallel in the CT. This allows the initially higher digitization costs to be allocated to several components, thus offering a cost advantage over optical measurement from the very first scan (e.g. in the context of statistical evaluations/ capability analyses). Compared to tactile measurement, the benefit arises from the absence of process paths, which leads to long runtimes, especially in the case of extensive measurement programs. With digitizing processes, on the other hand, these can be transferred to any number of additional components in a fraction of the time, which in turn makes shorter delivery times possible and, despite the effort required for scanning, keeps costs within an economical range. “Technologies and their applications are evolving rapidly. For example, it is possible to reduce artifacts in multi-material components in CT by using corrective software. This may result in further opportunities in analyses,” adds Lukas Tautz.

Your contact to the author for queries and technical discussions:

B. Eng. Lukas Tautz, Metrology

Phone: +49 2206 90851-100

Email: kontakt@barlog.de

Test123

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet,

More news