Andechser Natur glass yogurt spoon – BARLOG Plastics accompanies the development process from idea to series production

Developing a product that promotes a sustainable lifestyle, reduces food waste and strengthens the brand – these were the parameters set for a glass yogurt spoon for Andechser Natur.

BARLOG Plastics helped shape the entire development process for the Andechser Natur glass yogurt spoon project and supplied the required small series of 10,000 parts. From the idea to series production – as a reliable and experienced partner with customized service and concentrated project know-how.

Sustainable material selection as a basic building block

The material selection was quickly elicited by the given sustainability desire: KEBALLOY ECO R-PET, a new product series of tailor-made recycled materials that meet the strict requirements of food contact use and, like virgin material, are manufactured within a tight specification. The plastic is temperature resistant, food grade and dimensionally stable – making it the perfect material for a glass yogurt spoon.

“Material selection is one of the fundamental decisions engineers have to make to align a component,” said Florian Sembowski, project manager at BARLOG Plastics GmbH. “The properties and characteristics that define our materials are at the same time, of course, essential properties of the end product and determine, for example, its life cycle assessment.”

Rapid tooling process for small series

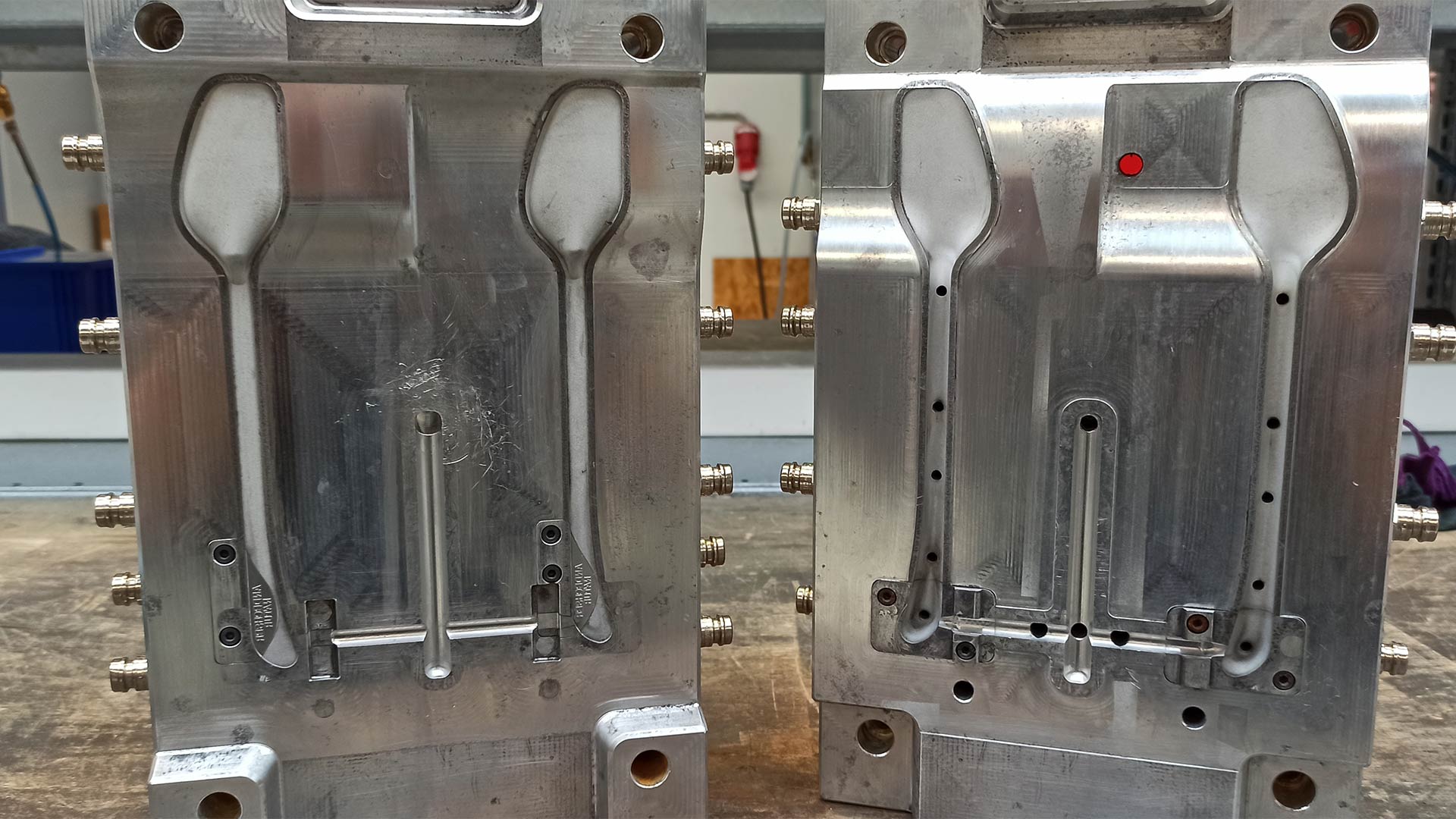

In close cooperation with our customer, the component design was optimized to suit the plastic, e.g. with regard to character embossing and draft angles. The small series mold was then designed and manufactured from aluminum. The desired surface structure in accordance with VDI 3400 reference 30 was also introduced by blasting the mold surface, so that finally the produced small series could be delivered to the customer as expected.

“Thanks to the chosen rapid tooling process, we were able to produce the bucket quickly and cost-effectively, reducing the time-to-market to a minimum,” says Peter Barlog, Managing Partner at BARLOG Plastics GmbH. “This saves time & costs and supports the efficient implementation process.”

Innovative and future-oriented end product

The result: A glass yogurt spoon was created that perfectly matches the glass shape of the Andechs glass yogurt thanks to the shape design and the incorporated curves. The possibility thus given to remove the yogurt completely from the yogurt jar reduces food waste at the same time. By choosing KEBALLOY ECO R-PET as the material, another criterion has been met: Sustainability. The spoon is made of 100% used PET bottles and has been designed for a long service life. Should consumers no longer use it after years, they can dispose of the spoon via the yellow bag/yellow garbage can.

“The sustainability aspect of plastic products is taking an increasingly important place in our corporate culture and strategy,” says Peter Barlog. “There is also a growing desire among our customers for sustainable solutions that contribute to environmental protection. We want to contribute to improving the environmental footprint of plastic products through material selection and the use of high-quality recycled plastics, but also through aspects such as recyclable design, high quality, repairability and durability. Plastic can be much more than cheap plastic that is disposed of as a disposable product after a short service life, namely a valuable raw material in a resource-conserving circular economy. The areas of application for this are manifold, please feel free to contact us. Together we will elicit the design and implementation possibilities for your sustainable product or component.”

About BARLOG Plastics:

BARLOG Plastics uses the Rapid Tooling process to process more than 300 customer projects every year – from food packaging, household electrical appliances and automotive components to medical technology – and processes a wide range of thermoplastics from PE to PEEK and from TPE to LSR. In addition to the high speed of the rapid tooling process, the holistic cooperation with other specialist departments , such as CAE services, CT metrology, test laboratory or material development, is a particularly important success factor in helping customers to bring their products to market as quickly as possible.

More news